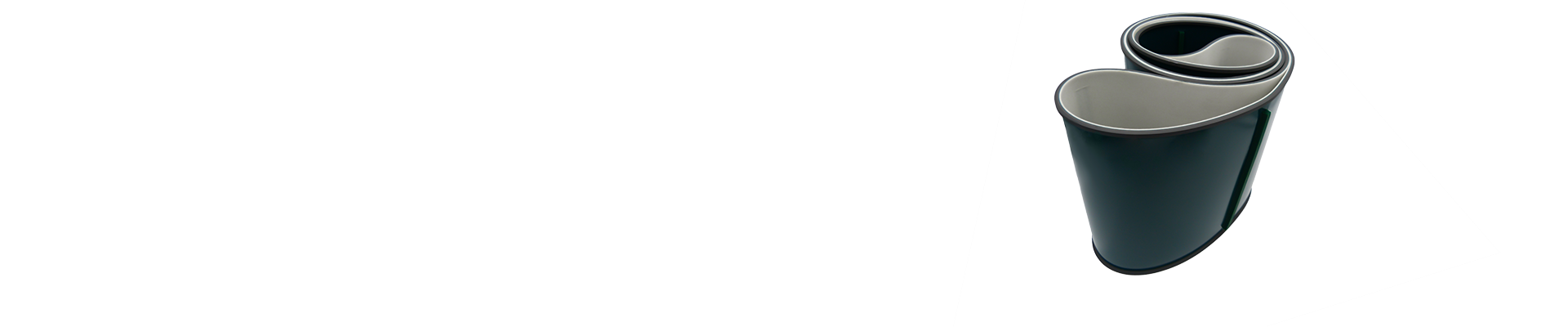

Conveyor Belts

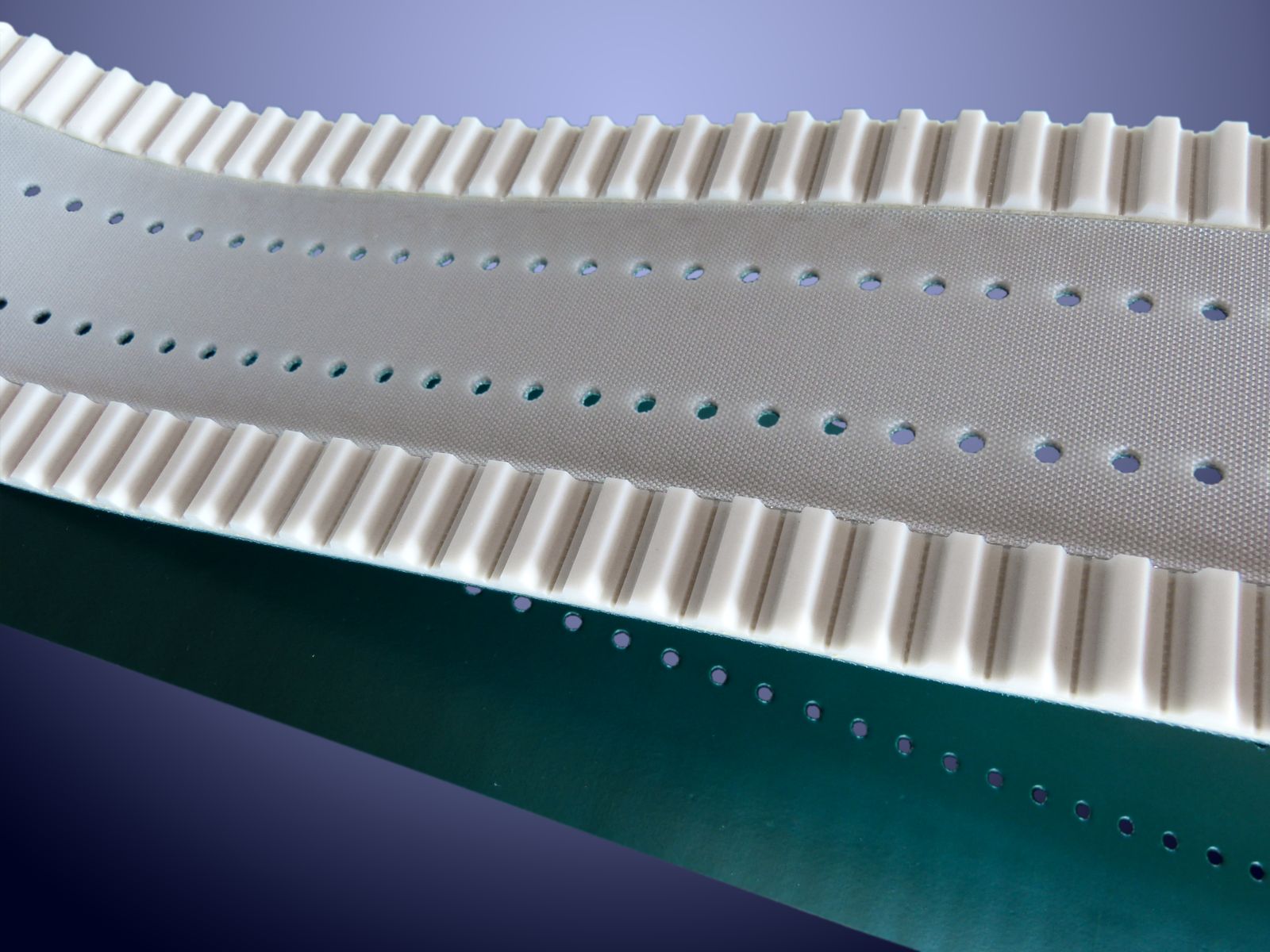

Synchronous belts are innovative systems which combine the advantages of timing belts (positioning precision and constant length) with the characteristics of smooth belts (flexibility and large widths).

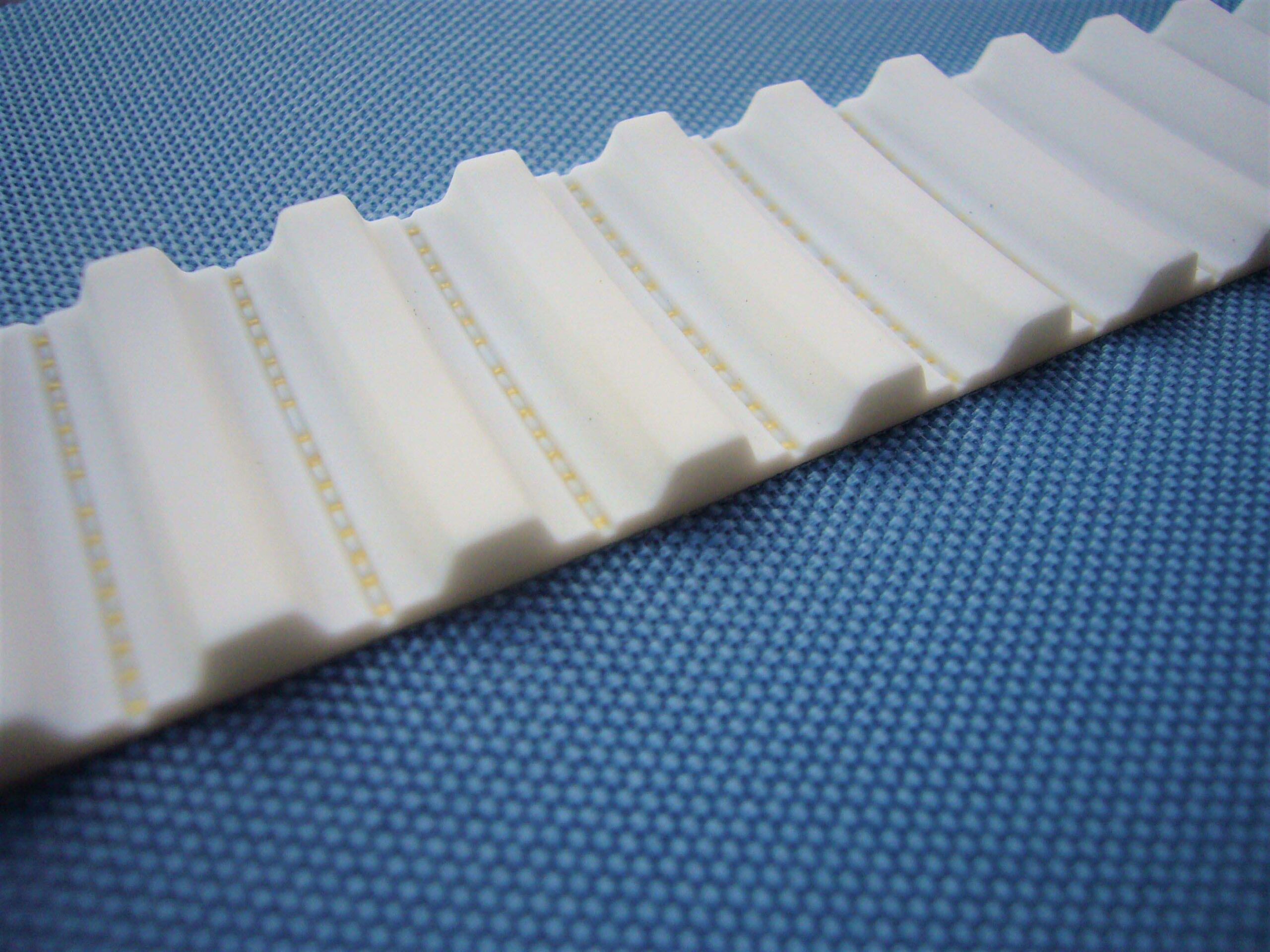

They are made by milling grooves on the rear of polyurethane belts and welding one or more timing belts (Kevlar cable), the strands in this system guarantee a constant length over time and allow the use of pulleys for timing belts both on the drive and idle shaft.

They can be manufactured with a maximum width of 1000 mm, and the types of teeth which can be applied to the belts are T10, T5, H, HTD, 8M, STD, 8M.

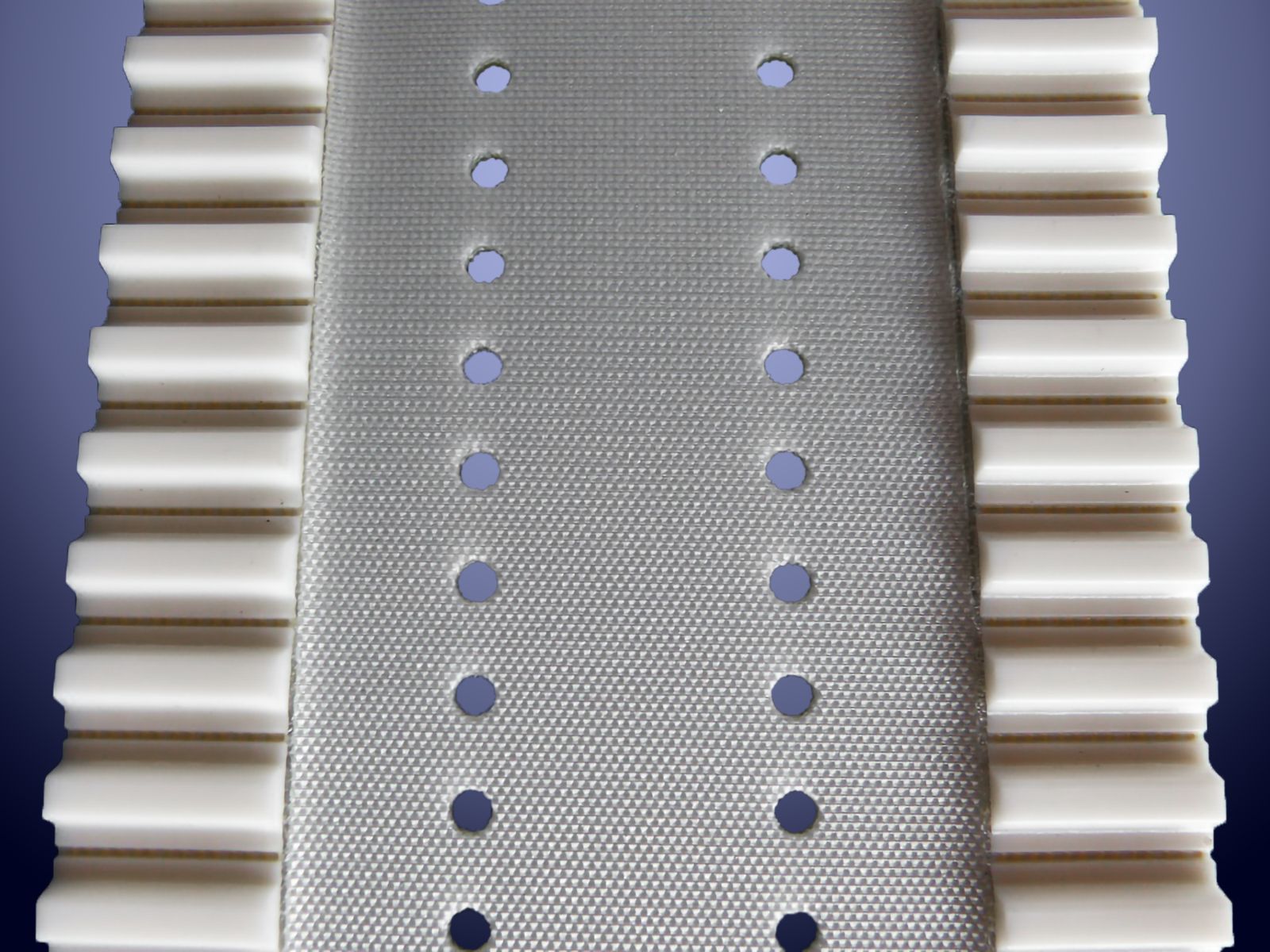

By making perforations in the inner part they can become excellent systems for vacuum transportation, and as the lower part of the belt is made from a low-friction material, the power required to drive the conveyor system is significantly reduced.

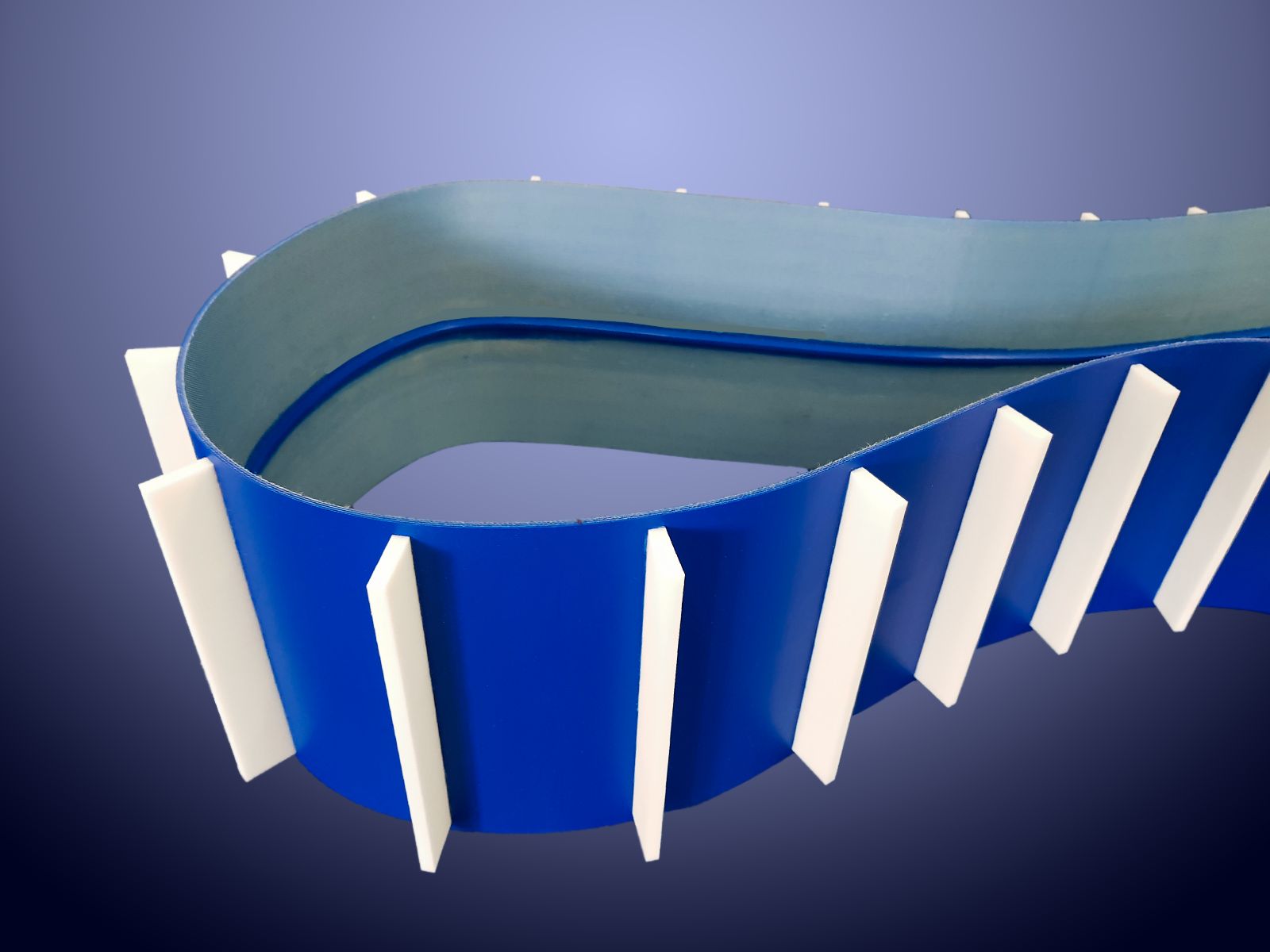

It is possible to apply attachments of any shape to the rear of the belt, and if required also side containment profiles to prevent the transported product from falling out at the sides.

When FDA approval is required, belts can be manufactured from food-safe polyurethane, and it is possible to weld attachments in certified materials to the rear.

When transverse forces or movement on a slope are present, it is possible to apply a central guide of trapezoidal shape K6, K10 and K13 to the inner rear of the belt.

Standard belts offer different solutions in terms of the surface which comes into contact with the product (high, medium and low friction), but in many cases different characteristics are required and it is therefore possible to apply dense or foam coatings.

There is a wide range of materials which can be used to coat belts, and like for the timing belts it is possible to use rubbers, polyurethanes and silicones which we can recommend by analysing the specifics of your application.

The use of foam coatings is suggested in cases where high deformability of the surface in contact with the product is required, and the most widely used materials for this type of solution are: Sylomer, neoprene and foam rubber.

In order to protect the foam and to increase the grip of the system, it is possible to apply a further, denser coating which is usually in silicone or rubber.