Conveyors

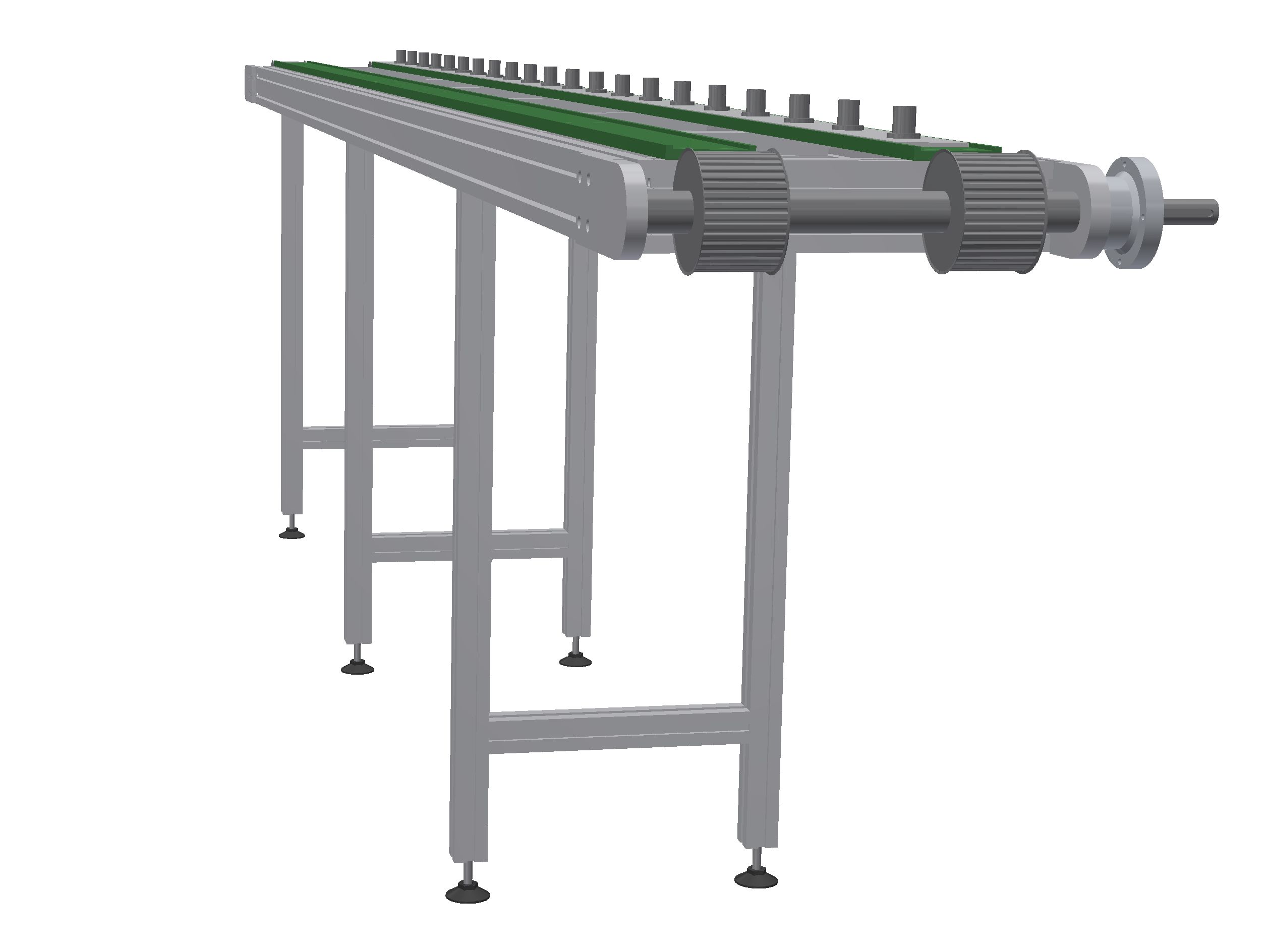

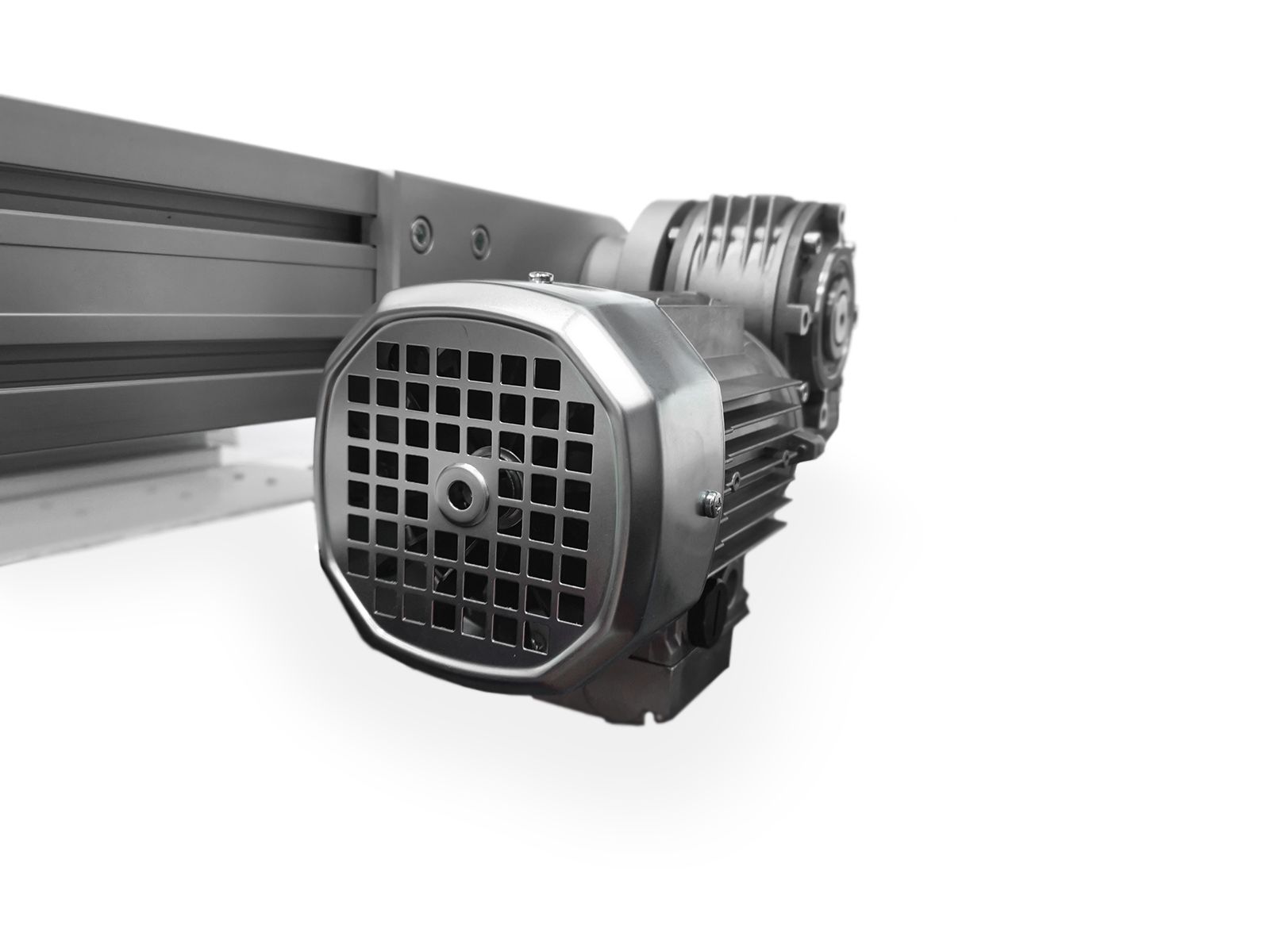

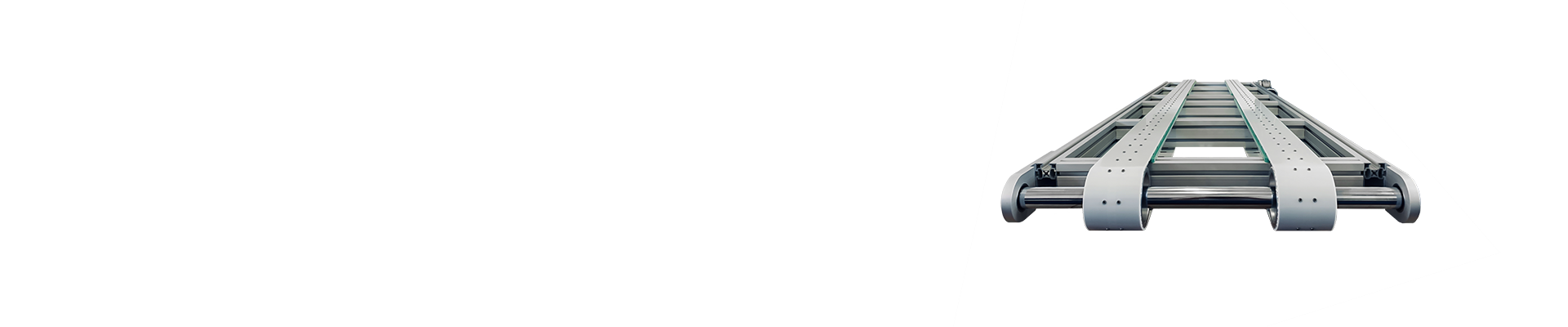

Our belt conveyors, with modular aluminium profile structure, are pre-assembled transport systems on which both timing belts and smooth belts can be installed.

Our experience in the field of timing belts has allowed us to create conveyor systems which are more precise in their positioning than traditional smooth belt conveyors.

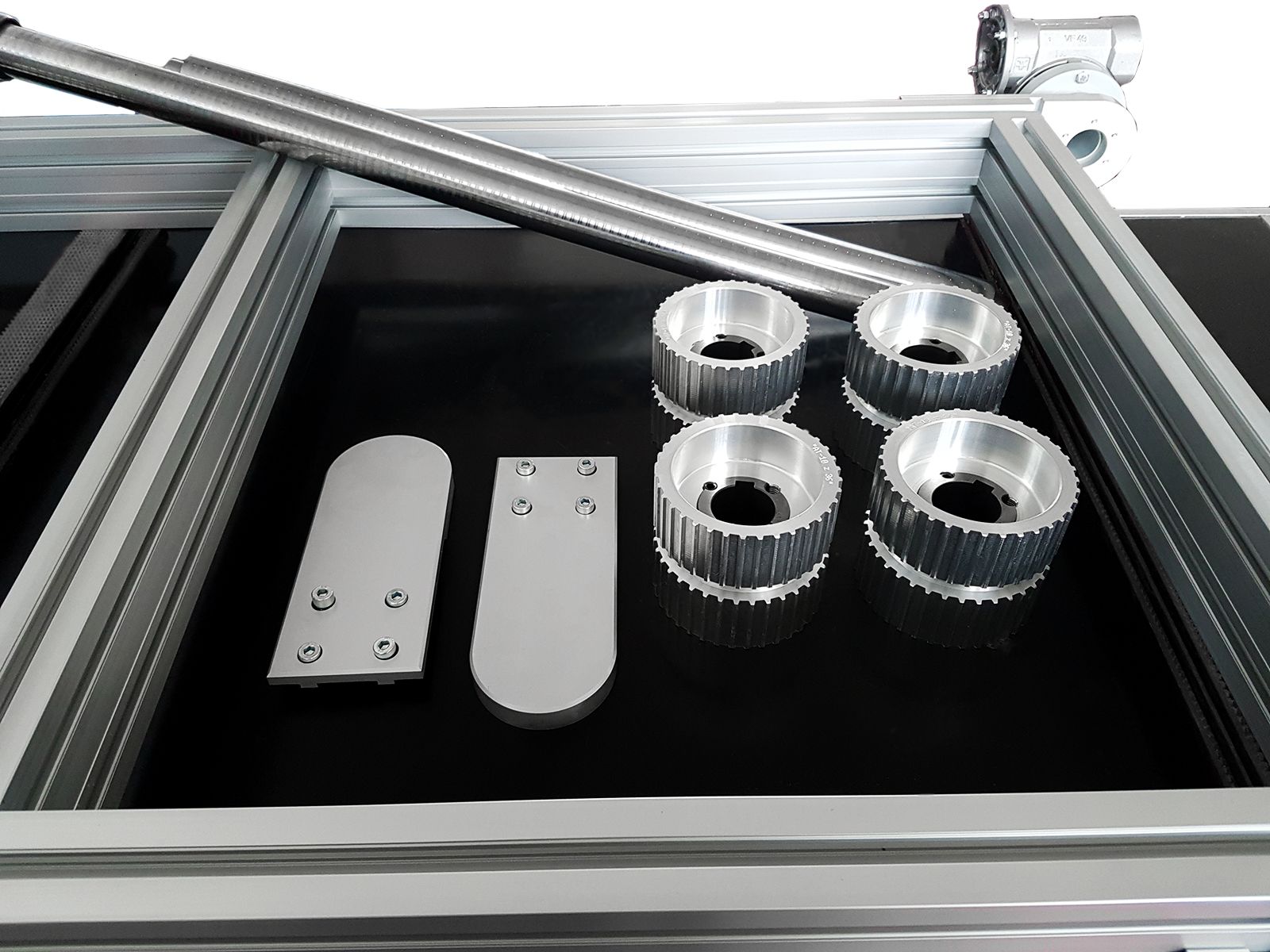

All types of timing belts, which you will find in the specific section of our site, can be used on conveyors, and we can use CAD to design a system which fits in perfectly with your requirements. Thanks to the system of adjustable polyzene profiles and pulleys with conical bush, the conveyor is highly versatile, allowing both the width of the timing belts and their position and spacing to be changed.

When the timing belt is particularly long, the conveyor can be broken down into two easily remountable parts, facilitating transportation and subsequent assembly of the entire system. The synchronous conveyors are usually used as feed systems or as movement systems where good positioning precision is required, and the sectors in which they see the most use are: assembly, automation, robotics, packaging, etc.

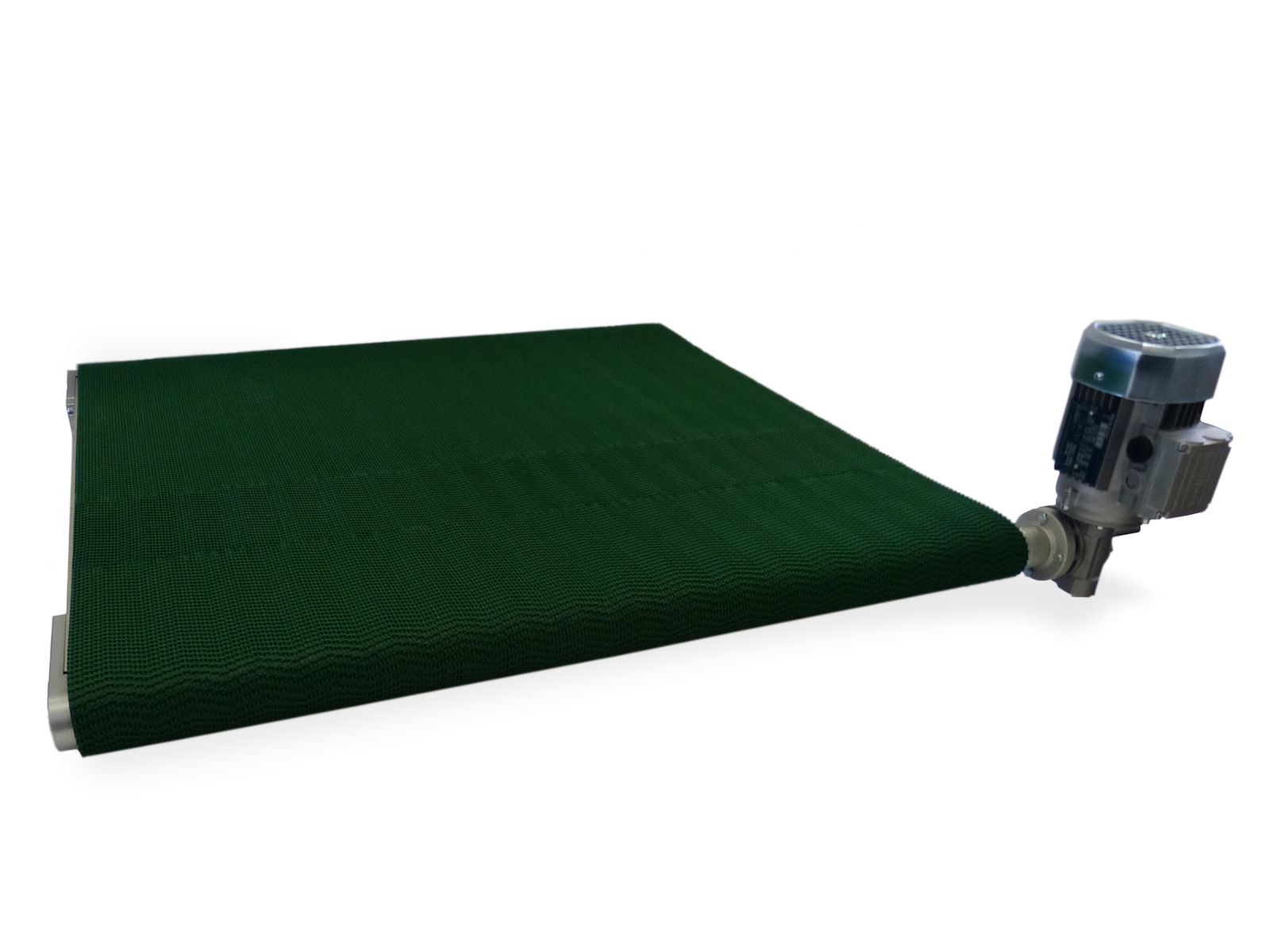

These belt conveyors, which do not have the synchronisation restriction of the timing belts, have the significant advantage that they can use tensioner rollers of smaller diameter compared to those of the pulleys used on synchronous conveyors.

Another aspect which makes this solution particularly versatile is the possibility to have both flat and inclined sections in order to be able to transport the product to different heights.

The current smooth belt market offers a huge number of standard solutions, guaranteeing a wide choice of the most suitable surface for transporting the product: many types of different materials, textures and grips make this system highly versatile and suitable for use in a huge number of sectors such as: food, packaging, robotics, beverage, paper, textile, non-woven fabrics, cosmetics, pharmaceutical, medical, etc.

As well as the more standard solutions, the belts can be customised in various ways: it is possible to weld attachments to drawing specifications, coat the back with different materials (dense or foam materials), apply a central guide to keep the belt on its axis, or side profiles to contain the transported product.

In order to protect the foam and to increase the grip of the system, it is possible to apply a further, denser coating which is usually in silicone or rubber.