special bearings

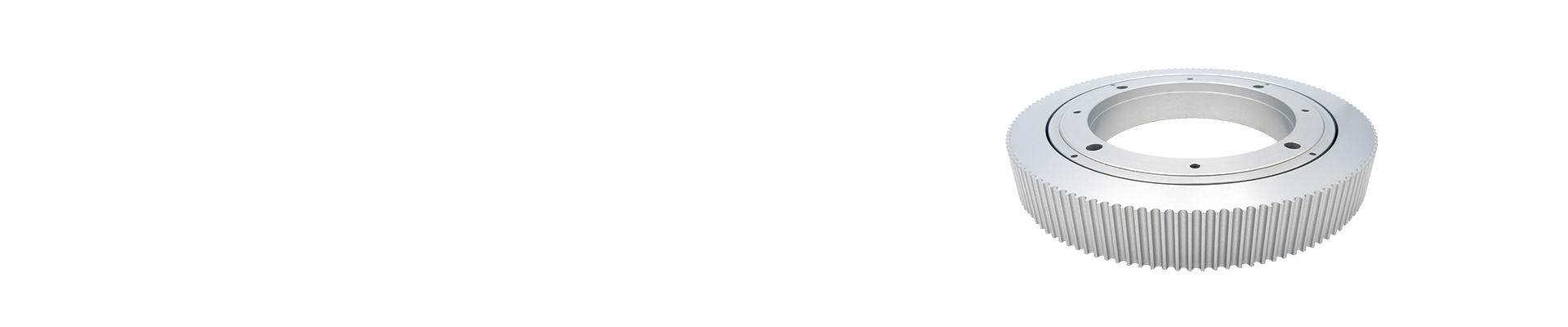

Dynamic 360 bearings and slewing rings to drawing specifications are highly versatile rotation systems, as their external geometry is made to measure, allowing the use of any type of material.

Over 20 years’ experience with integration of frankesystems allows us to provide a complete service which ranges from sizing and integration of bearing elements right through to manufacturing the component to drawing specifications.

The technology at our disposal allows us to design the bearing geometry internally and supply the 3D file of the component to allow the customer to check it is perfectly suited to their project.

Our experience in the sector of timing belts and gears has allowed us to create a range of bearings with external teeth, both in steel and in aluminium.

The generators we use are certified and available in the following belt pitches: AT – T – XL – L – H -XH – HTD – RPP – ATP – GT; we are also able to create outer rings with straight and inclined teeth from 1 to 6 mm module

We can use the materials best suited to the type of application and the corresponding operating environment; those most commonly used today are: aluminium, C45, stainless steel, plastic …