Foams to Drawing

Specifications

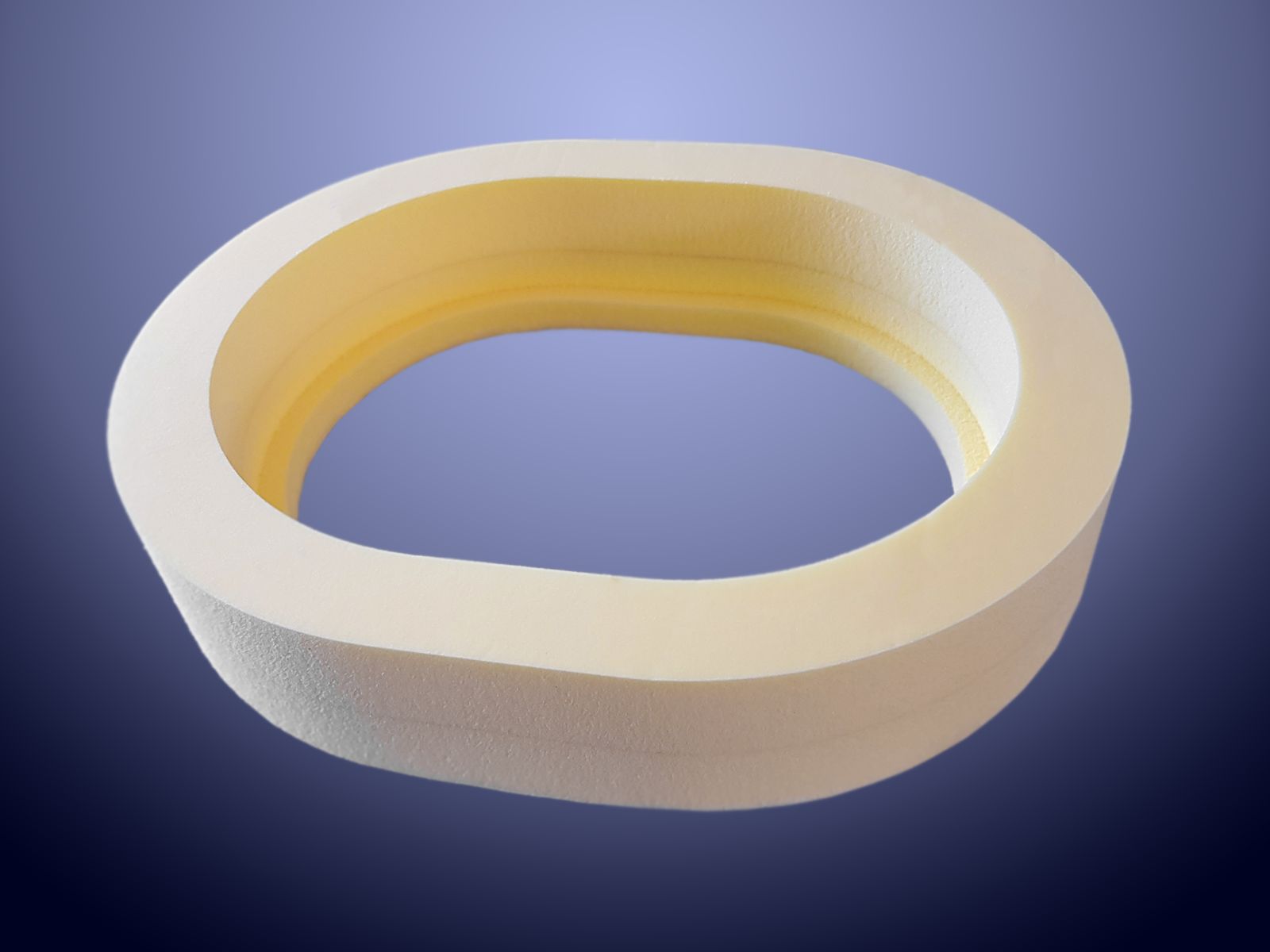

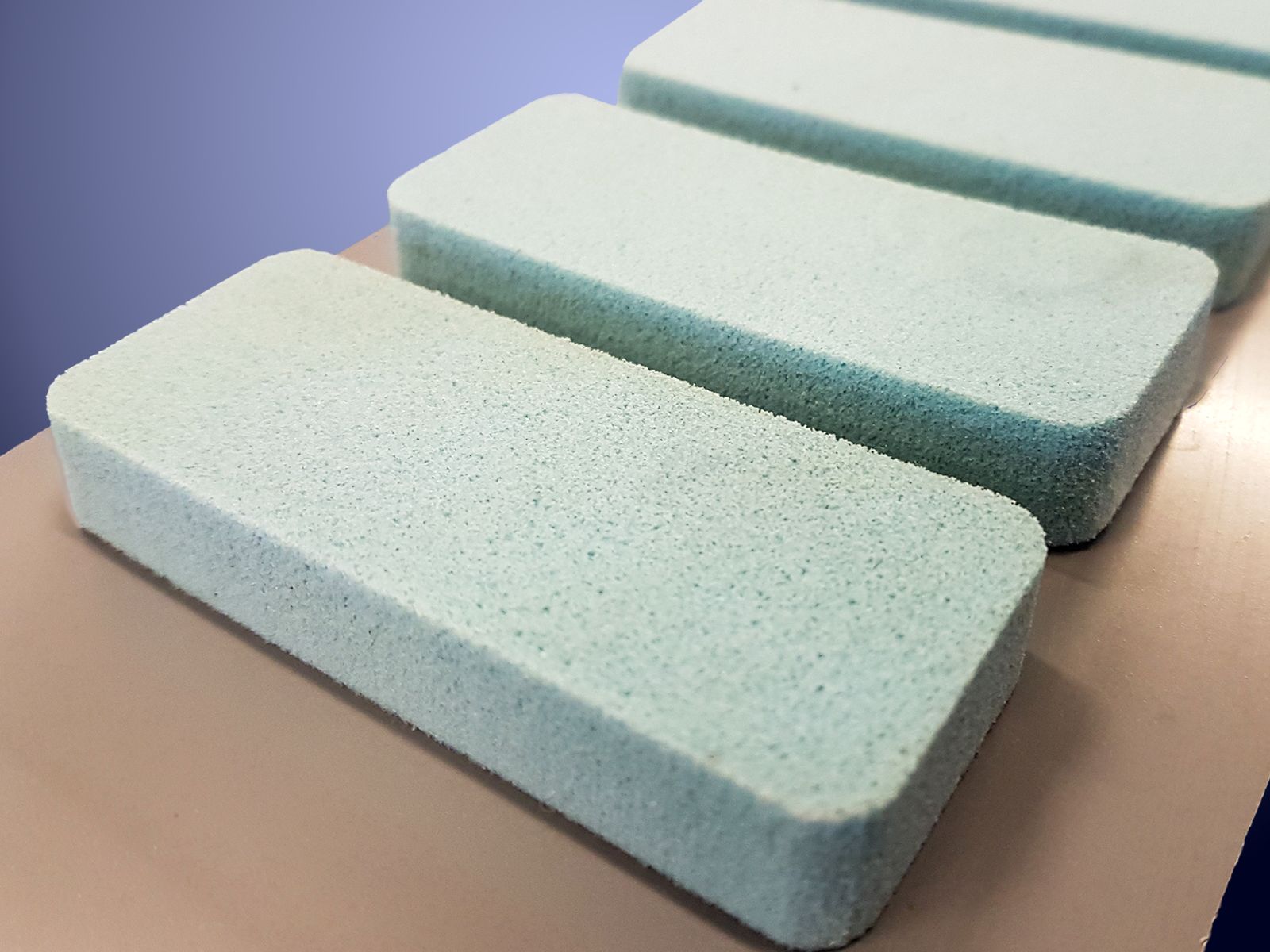

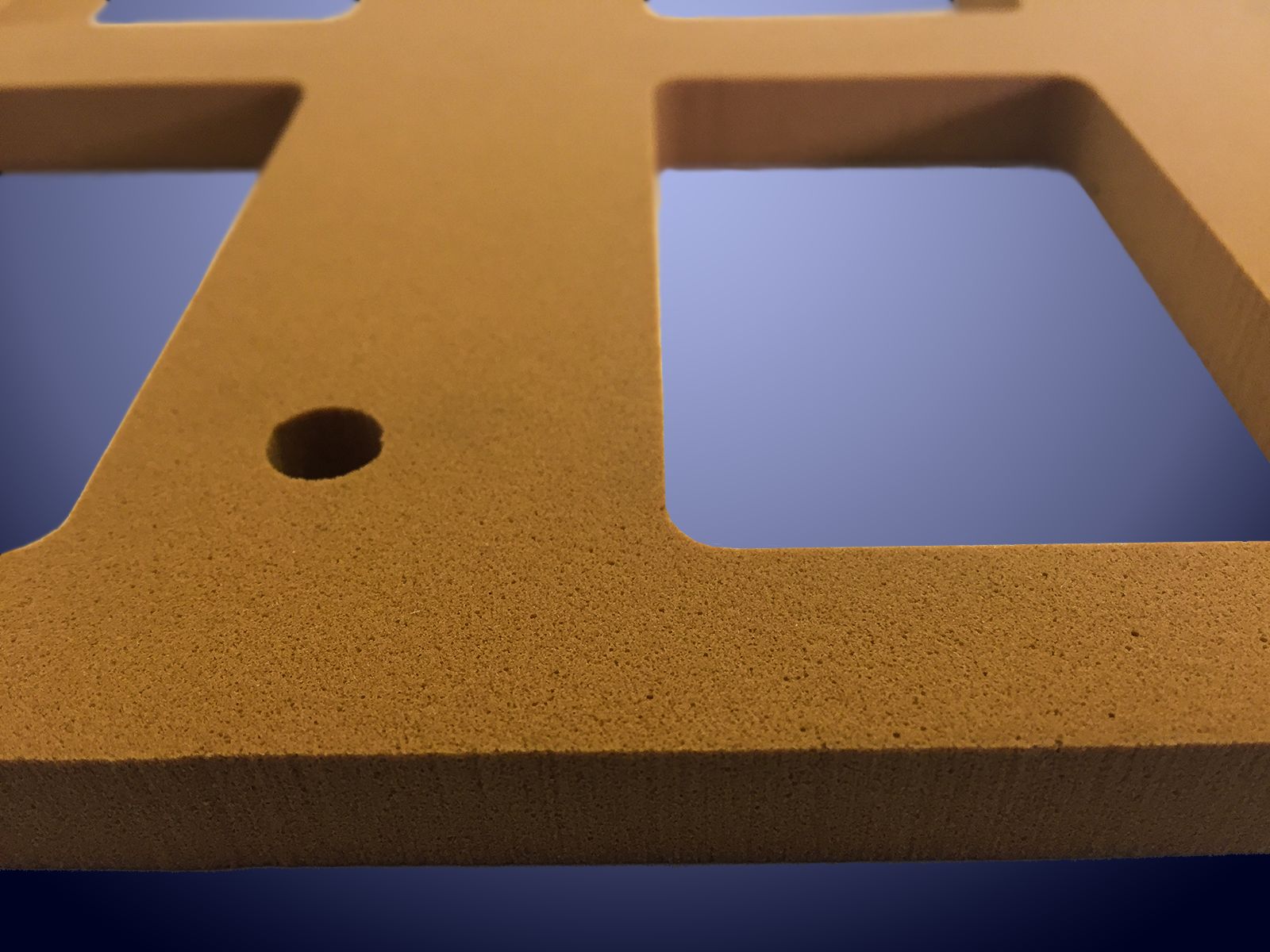

The desire to achieve perfect machining of foams has led us to invest in technologies which allow us to design components quickly, but above all to manufacture them to very high standards of quality.

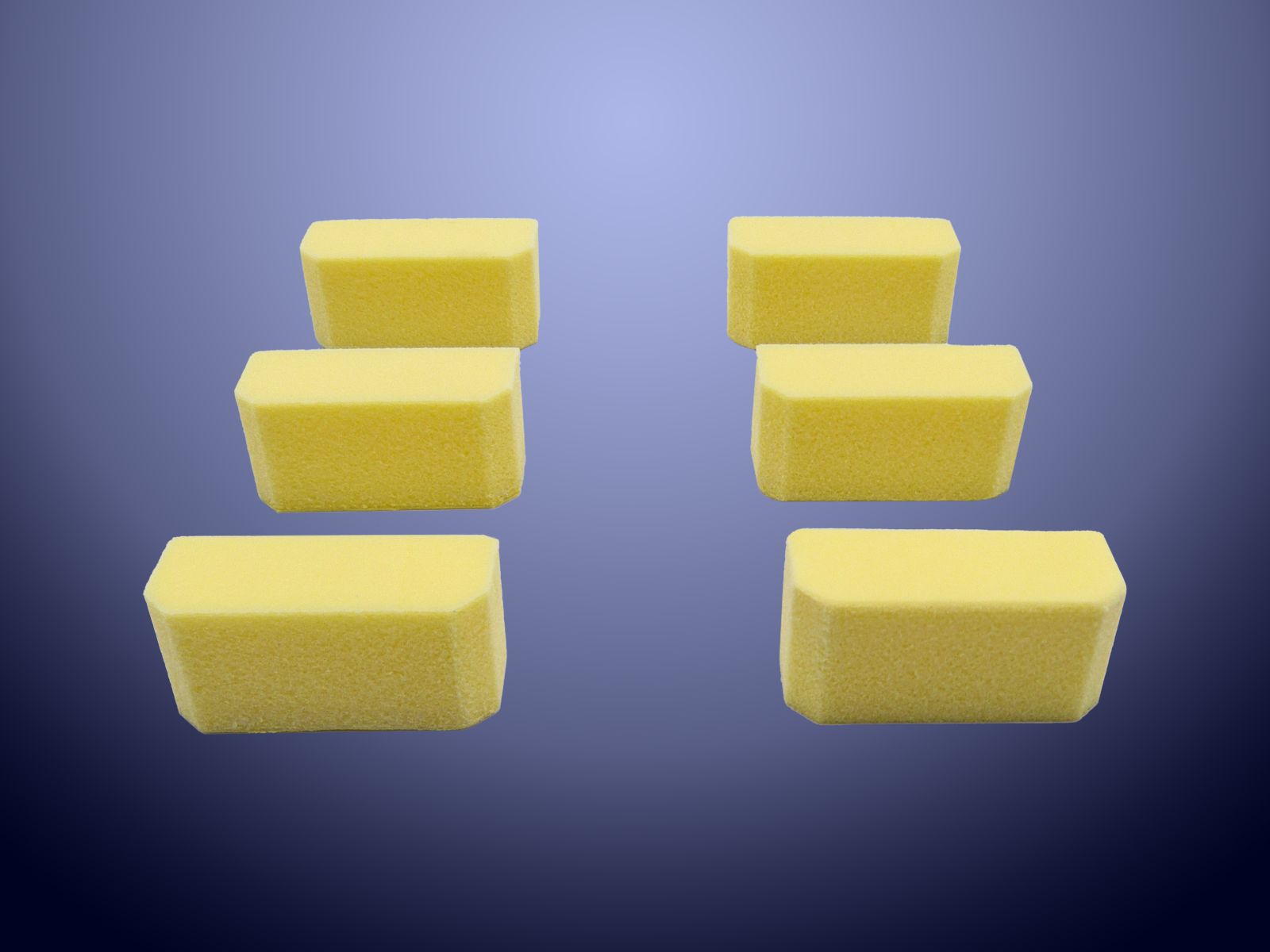

A cutting-edge milling machine combined with a range of specific tools allows us to machine all types of foam; its granite structure and high-speed spindle (40,000 rpm) also mean we can machine materials with very low density, such as yellow Sylomer (150 kg/m3).

Unlike waterjet cutters, which can create only open geometries, our technology allows us to create closed pockets or hollows at the different heights required by the design geometry.

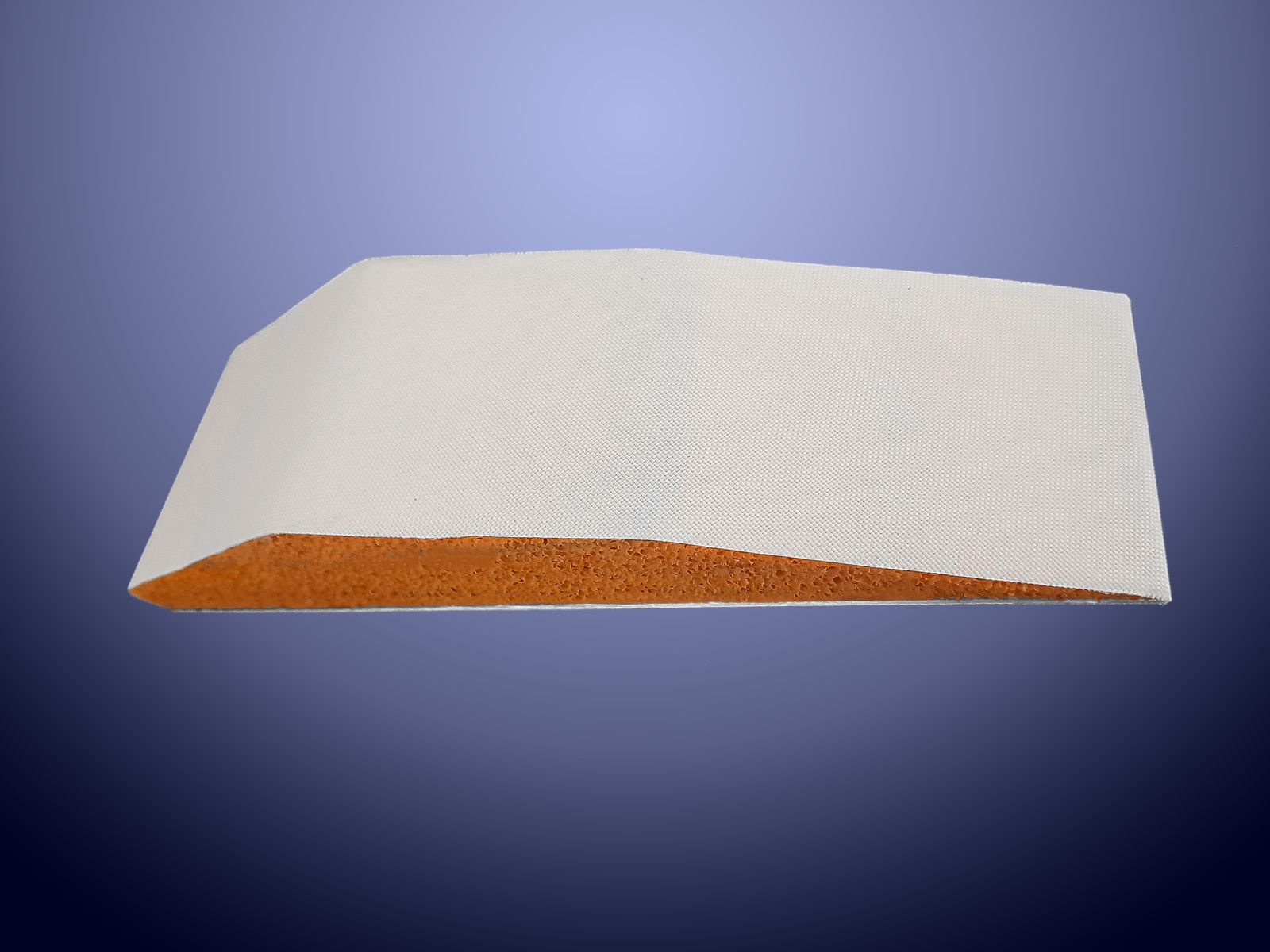

Foams are highly deformable, but they are less resistant to wear and offer less grip than denser materials; for this reason, we can apply coatings to the manufactured components, ranging from rubber and silicone materials to low-friction and anti-wear plastic fabrics.

As well as polyurethane foams, we also use other materials such as neoprene and foam rubber, and we can also manufacture substrates in other materials to which they can be stuck, such as aluminium, carbon-fibre, steel, stainless steel etc.

The sectors in which this type of product is most widely used are: food, packaging, industrial automation, robotics, beverages, paper, textiles, non-woven fabrics, cosmetics and so on.