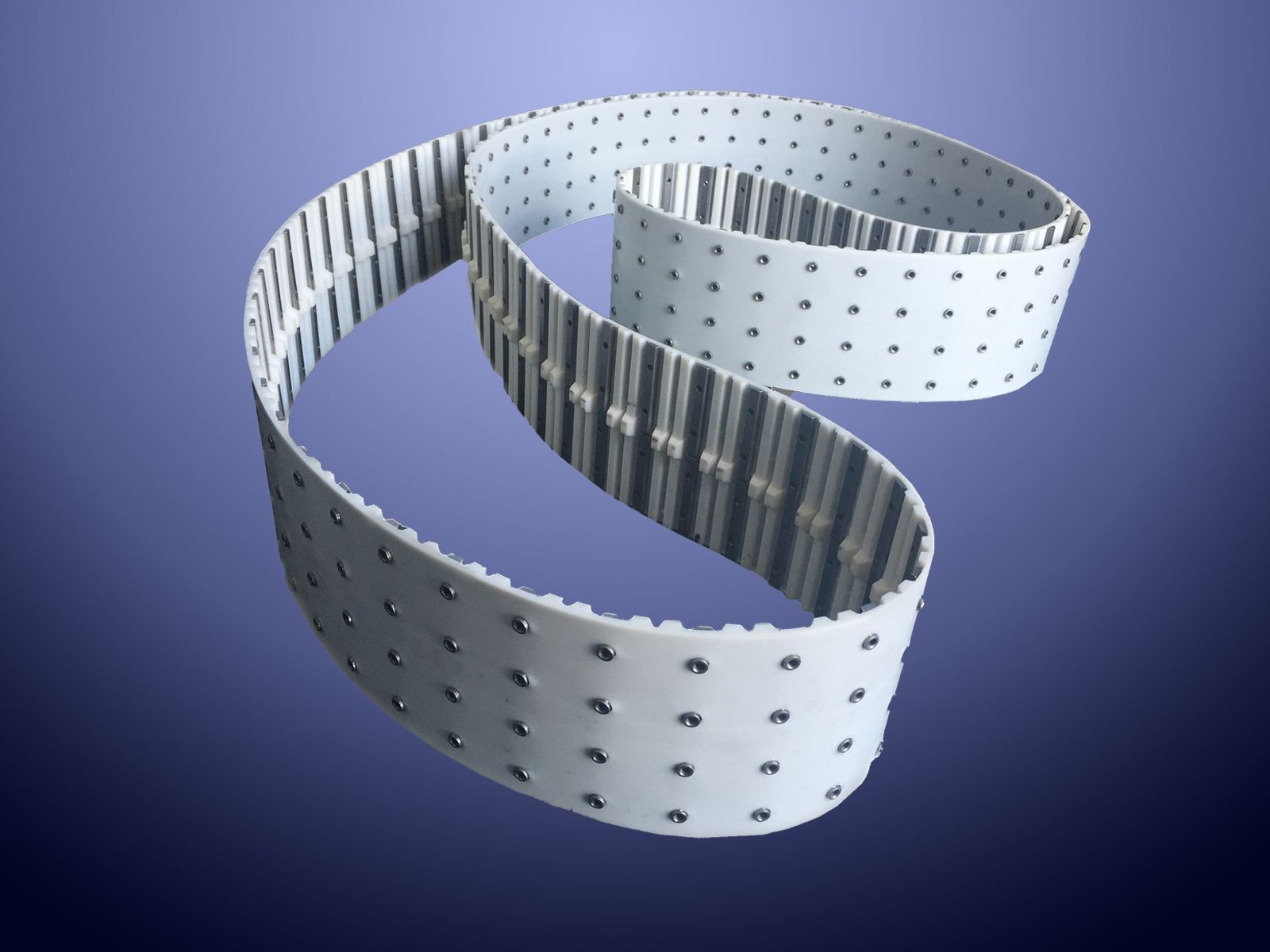

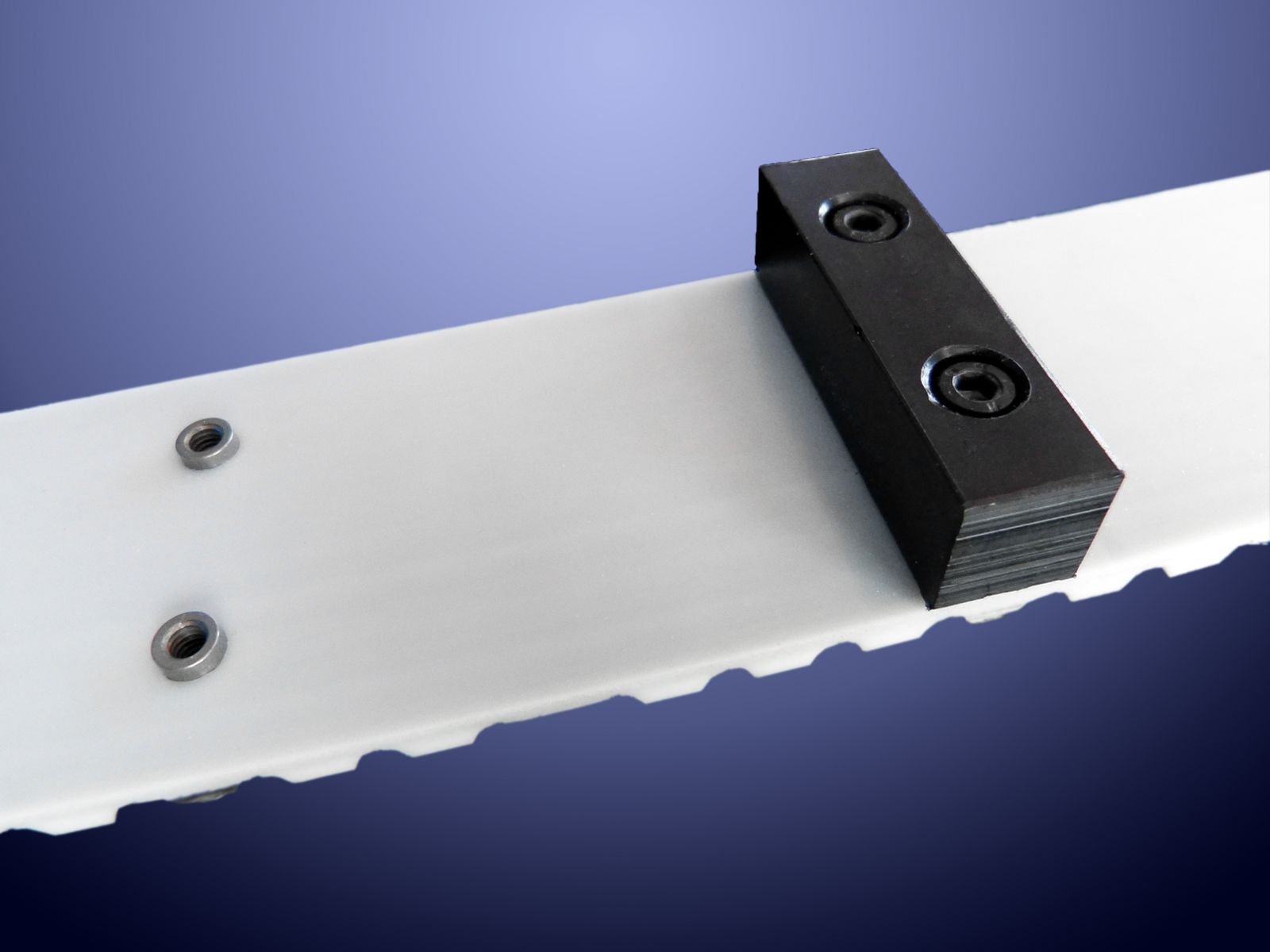

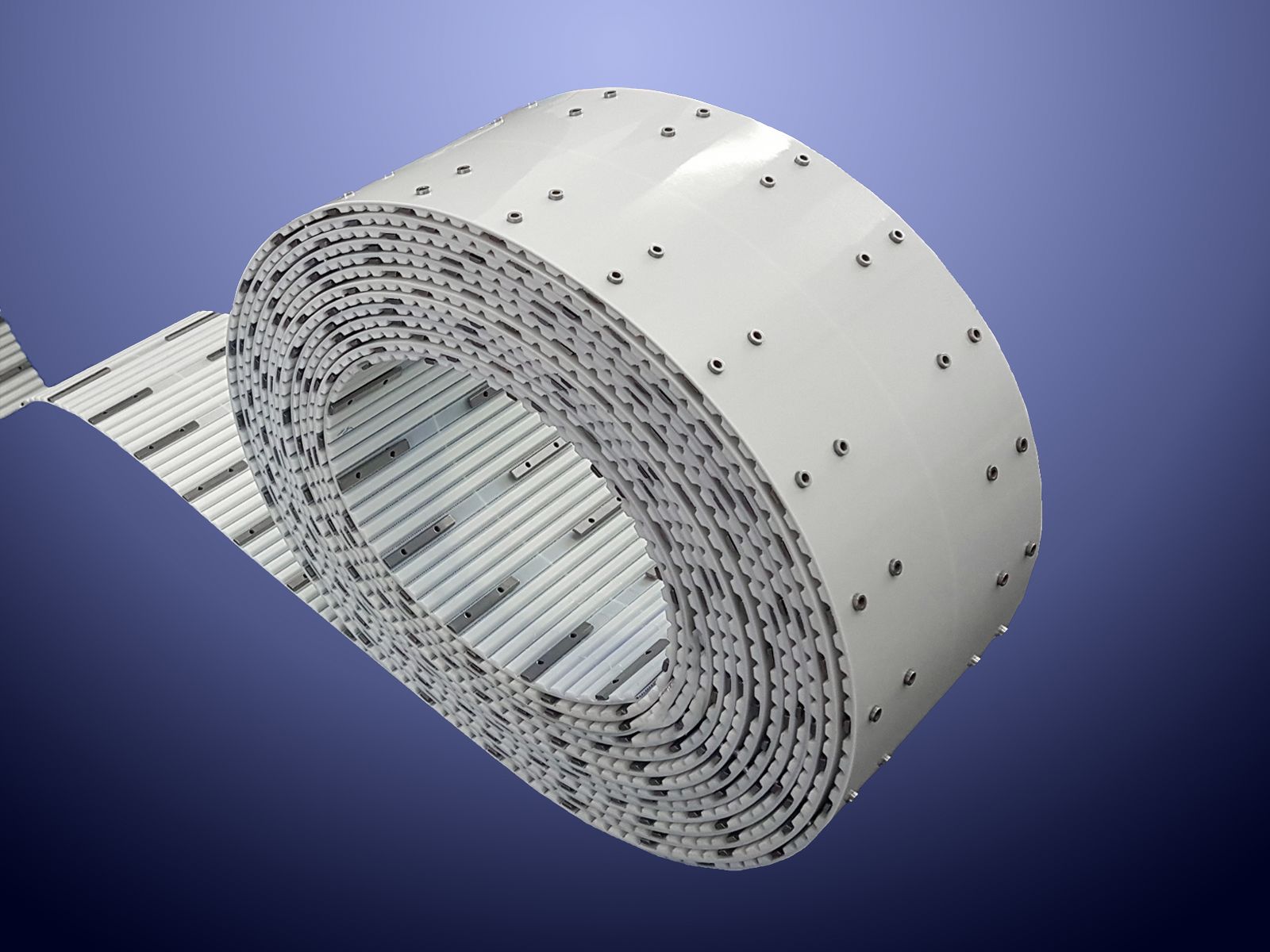

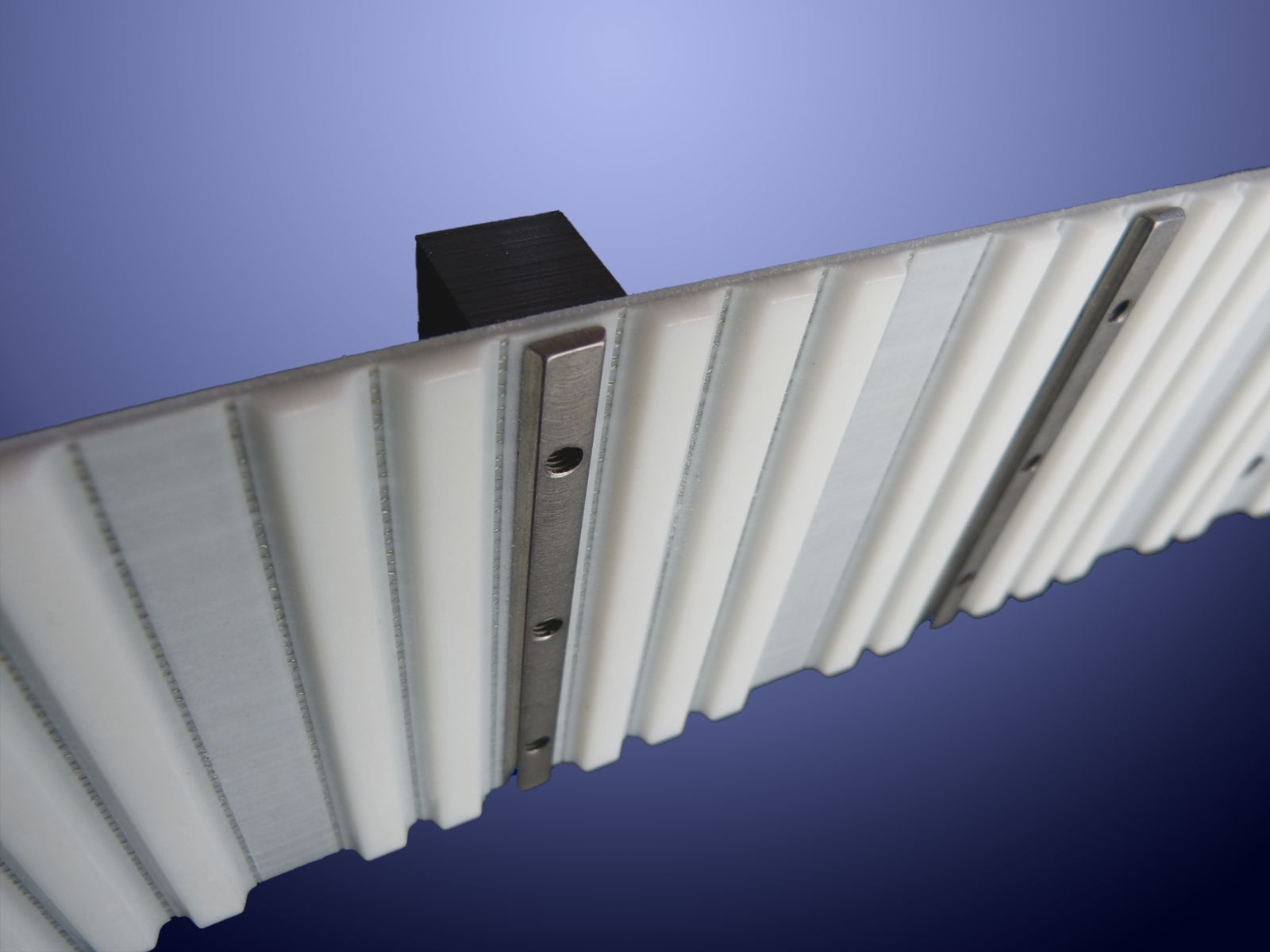

False tooth technology allows timing belts to be transformed into a highly reliable synchronous transport system which combines the robustness of the mechanical system with the flexibility in the choice of materials provided by attachments. Timing belts with false teeth in stainless steel (AISI 304) are widely used in the automatic machinery, packaging and industrial automation sectors. The machining to be performed on the timing belt is chosen by the customer, who can select both the distance of the attachments and the centre distance of the fastening bushes (the system can be supplied with all pitches, but it is recommended to use it with AT 10 timing belts). As we have warehouse availability of all the most widely used false teeth models, we are able to supply the complete system (timing belt with false teeth) with very fast turnaround times, and for those looking for false teeth only, these can be shipped immediately. (25, 32, 50, 75 mm).