Timing Belts

for the Food Sector (FDA)

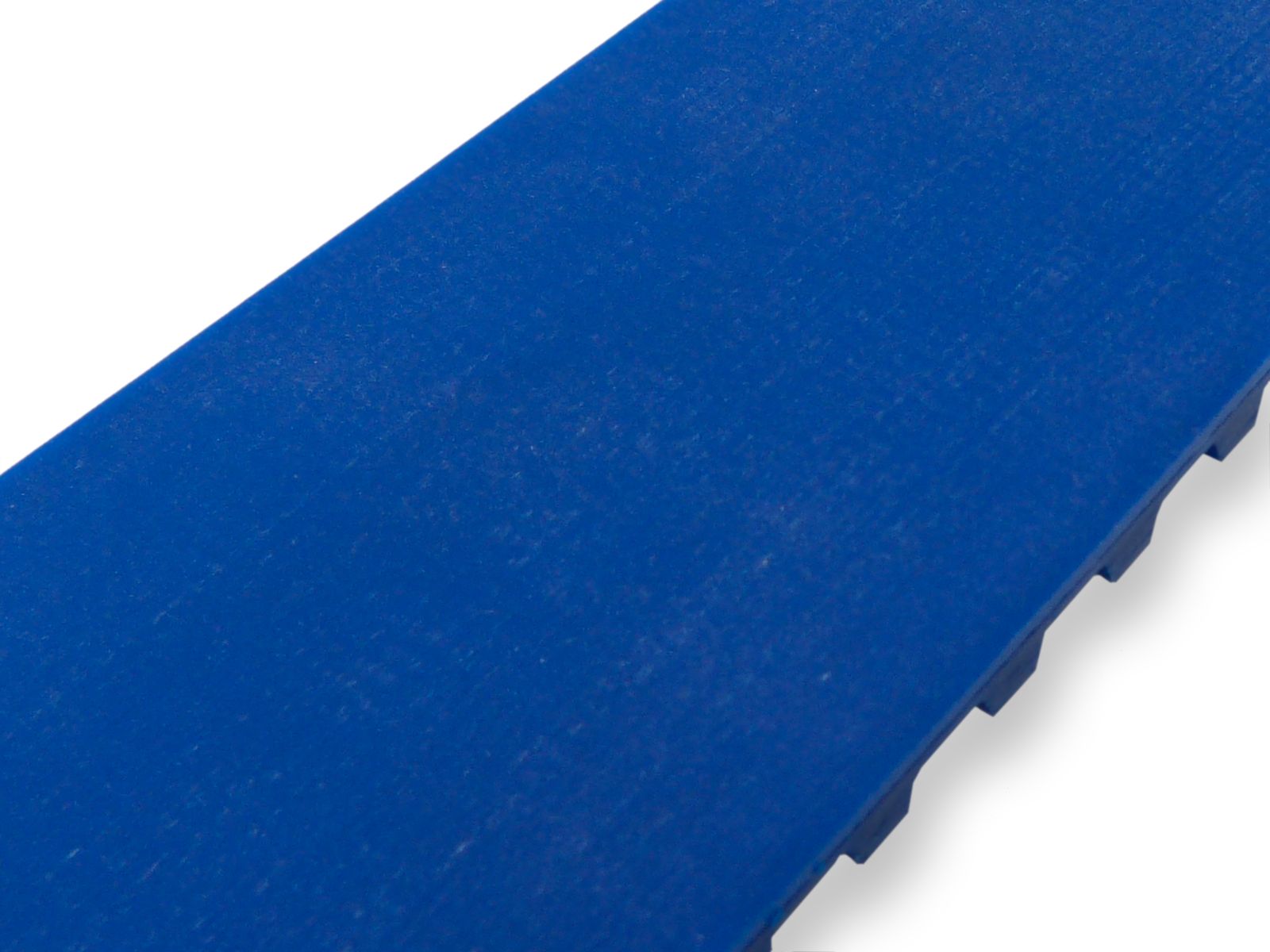

This type of product is characterised by the fact that the thermoplastic polyurethane used to produce the belt is FDA certified; it is usually blue in colour, with variable hardness from 60 to 90 shore.

These types of belts are produced by the metre, and are supplied in closed loop via welding or with the use of a mechanical joint; the maximum width which can be produced is 300 mm, and the available pitches are AT, T, L, XL, H with the internal strands usually in kevlar; in some cases it is possible to supply stainless-steel cables.

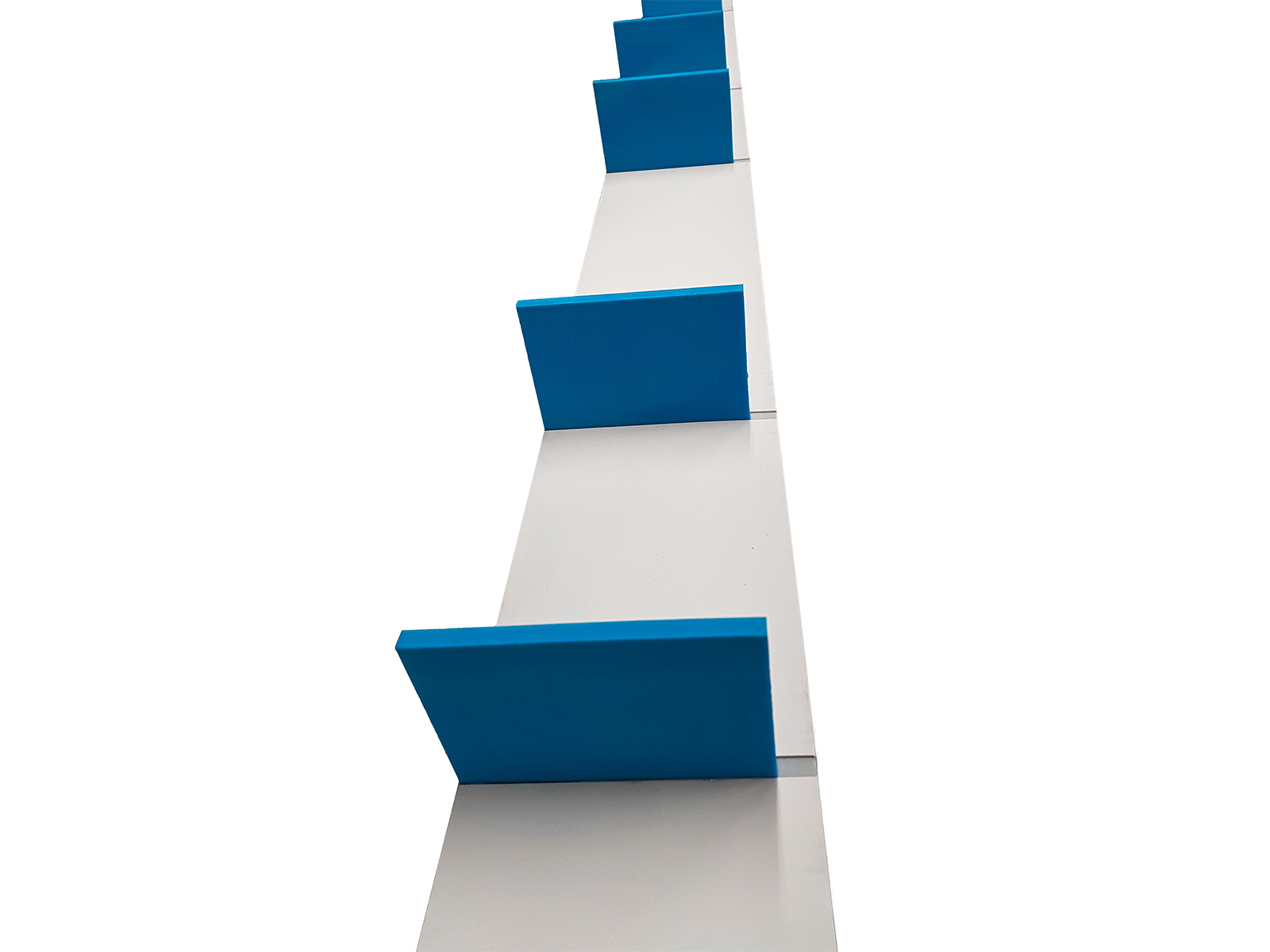

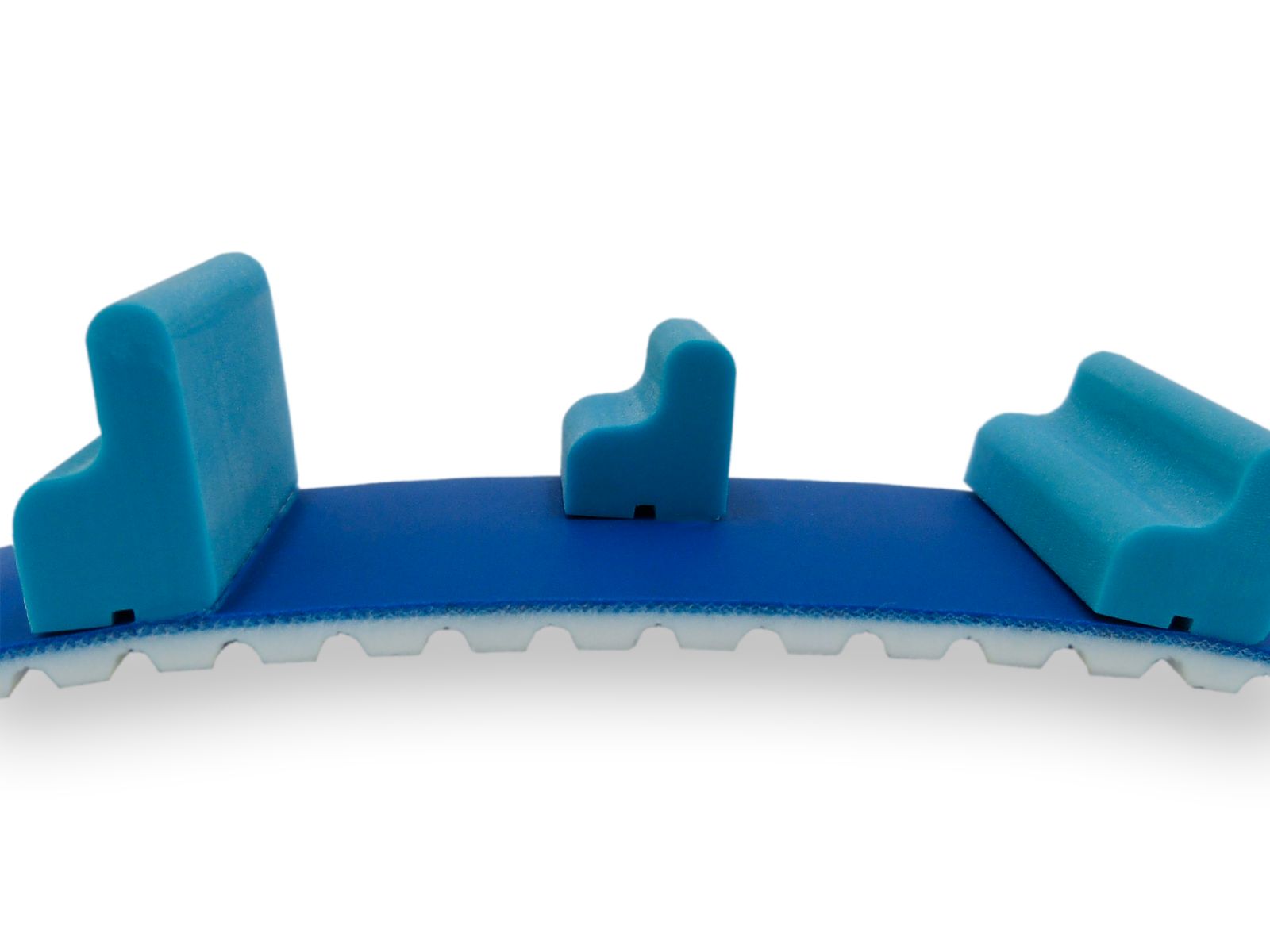

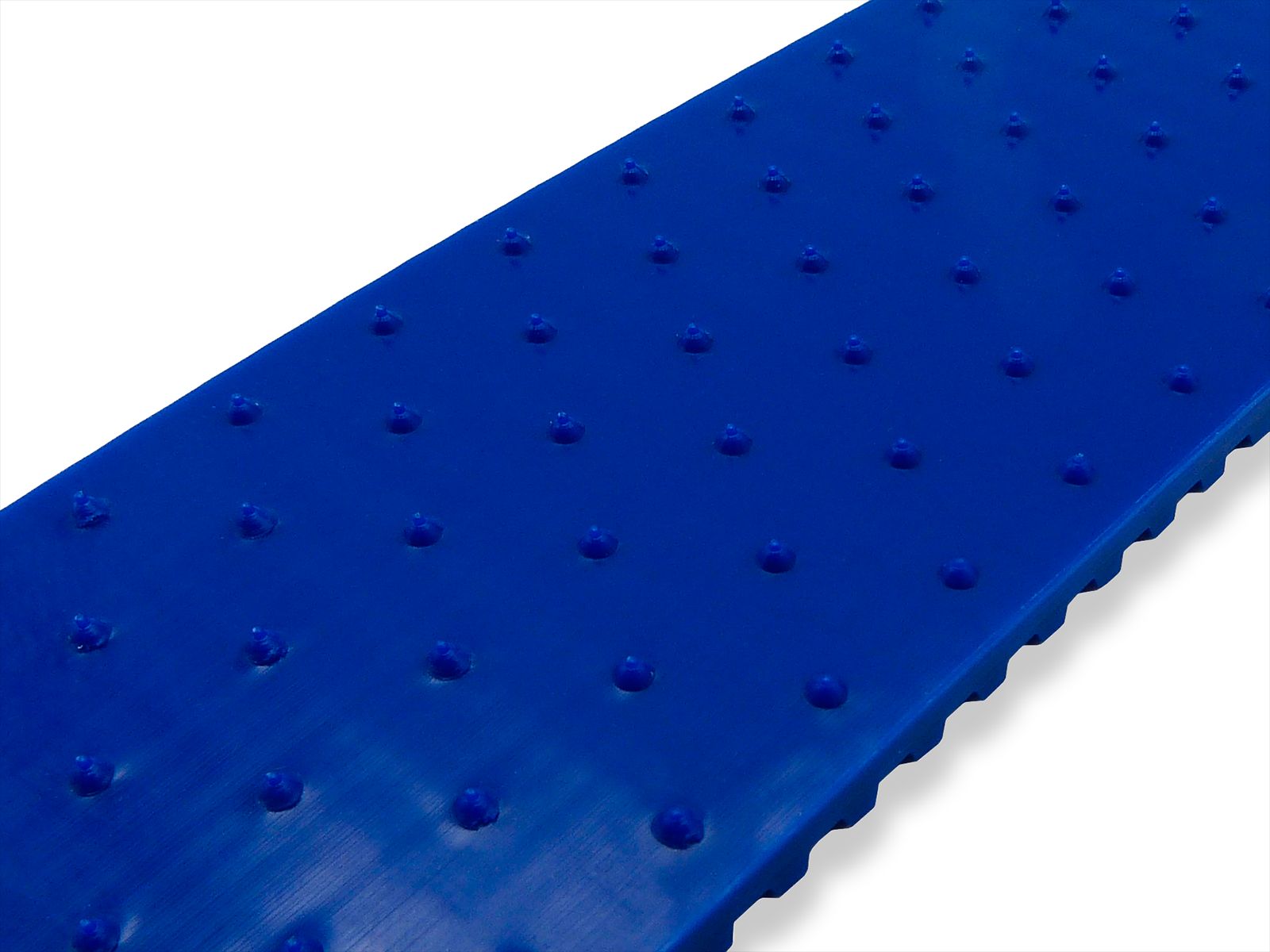

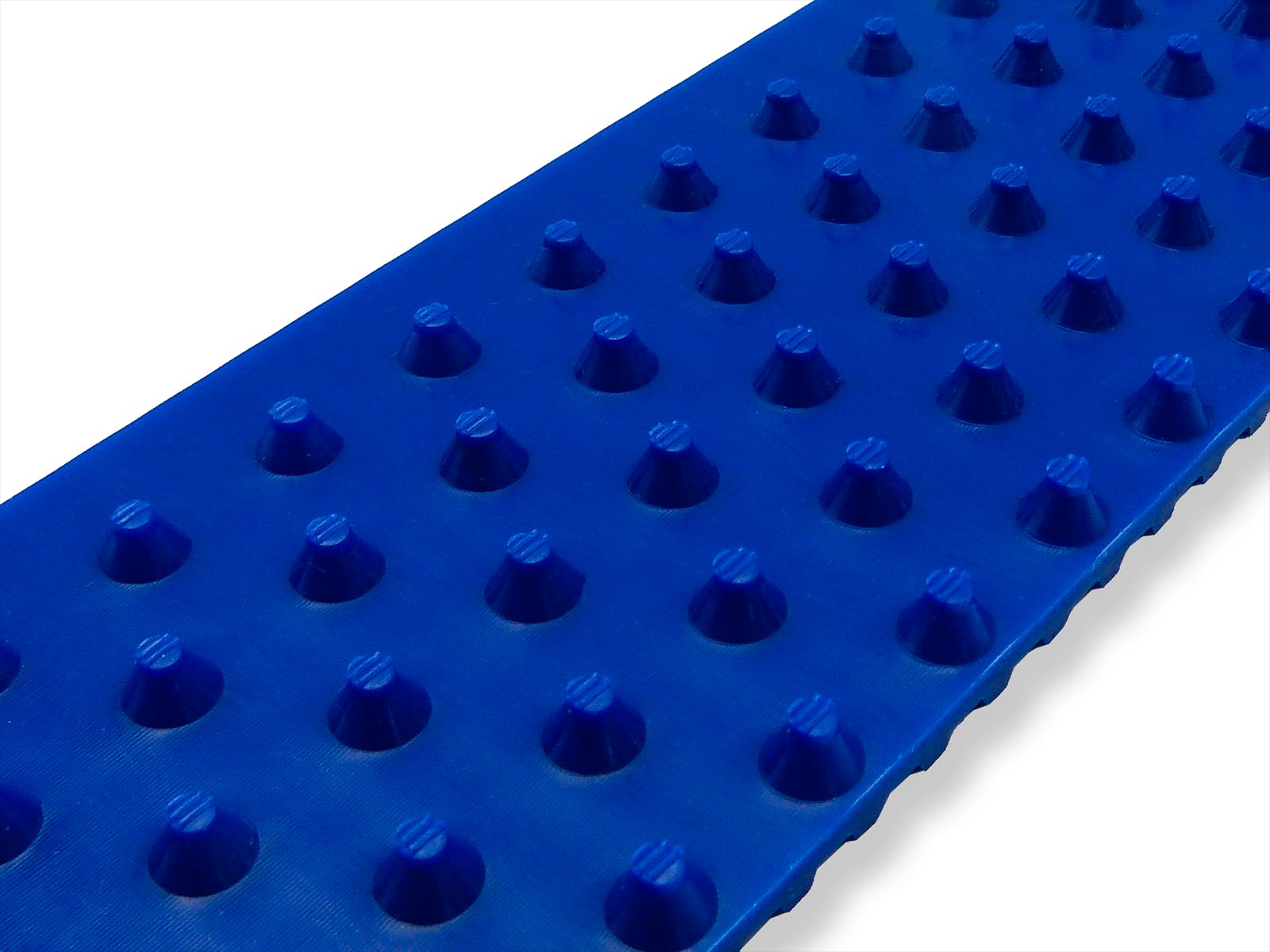

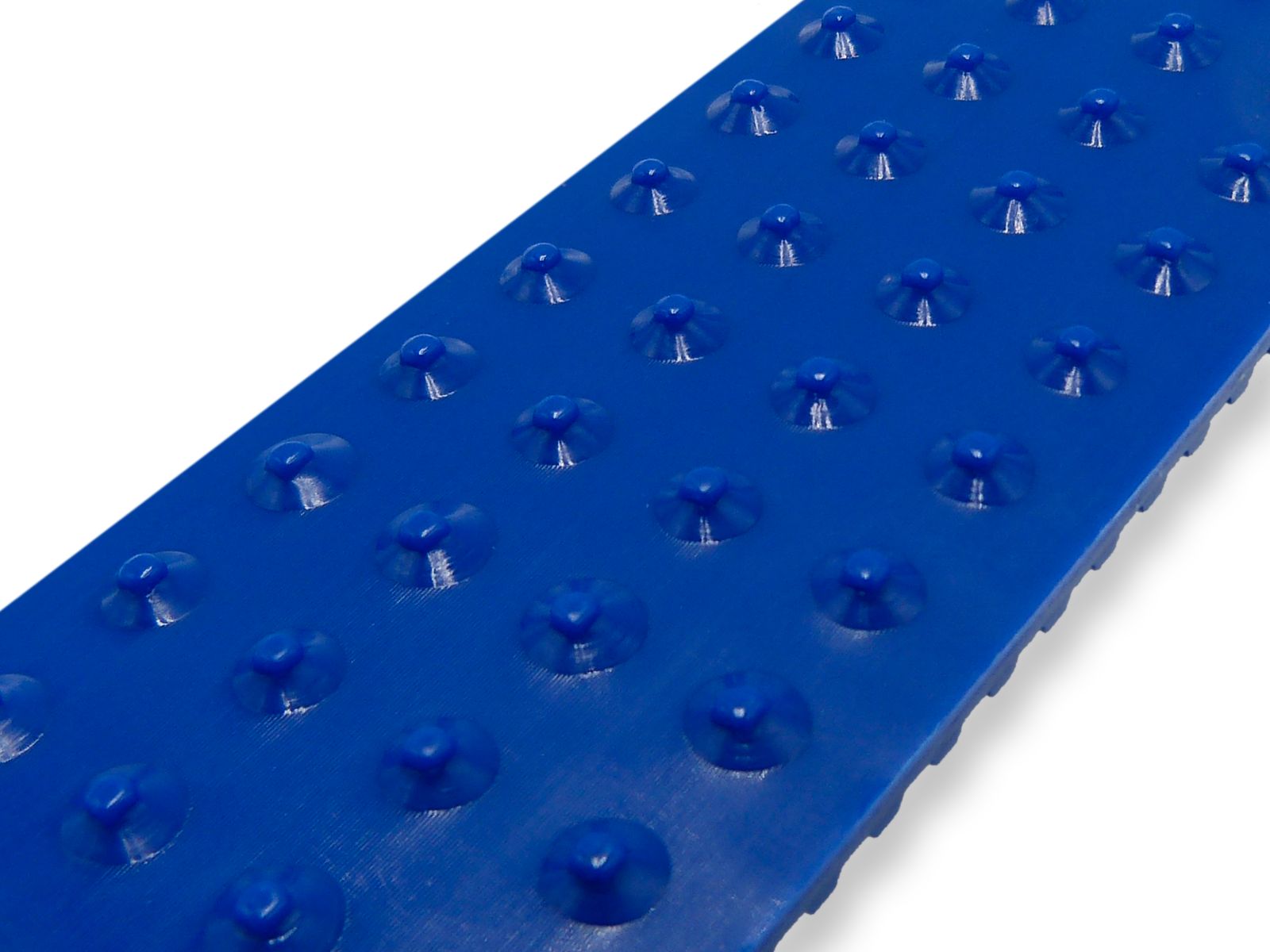

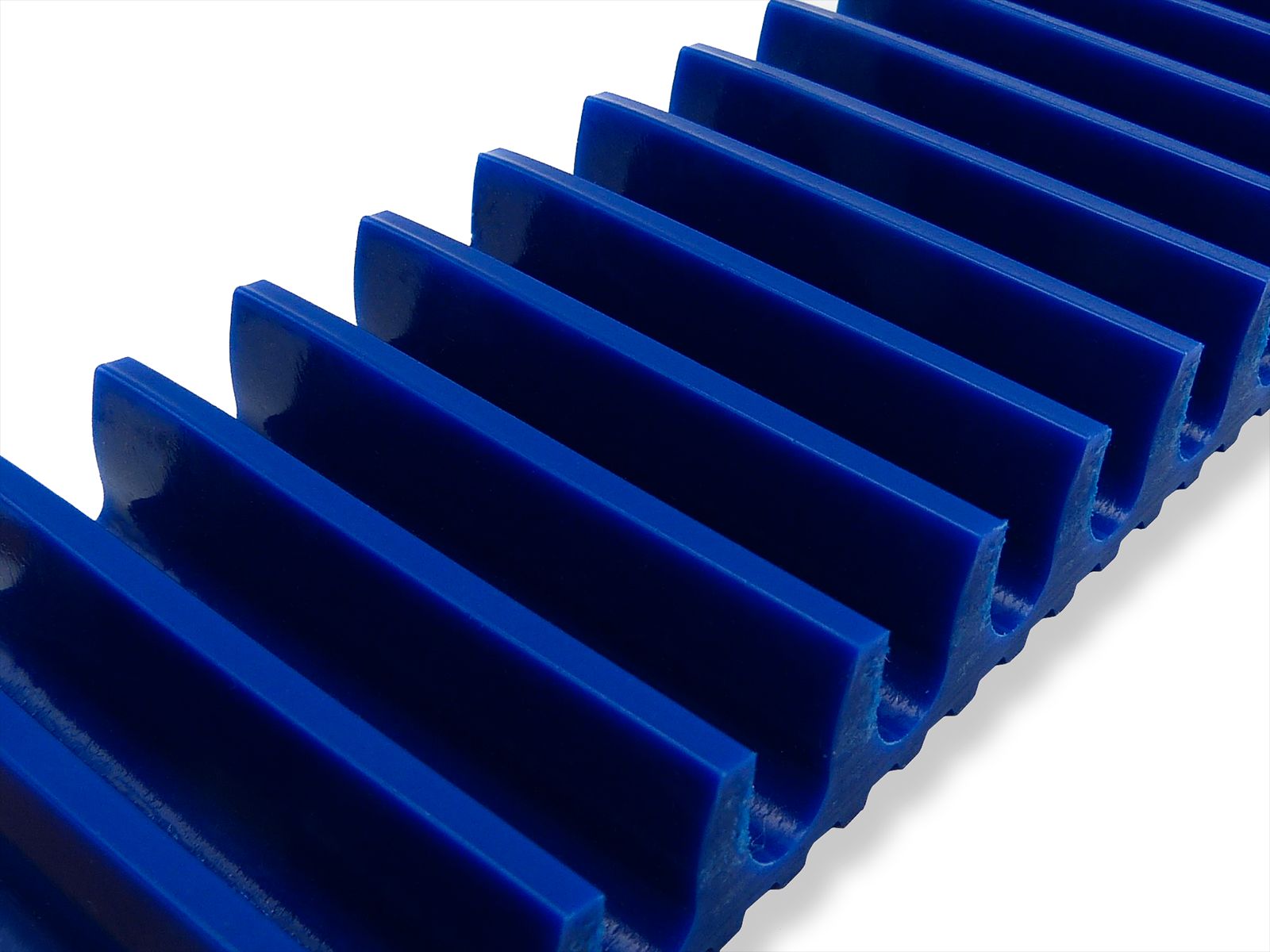

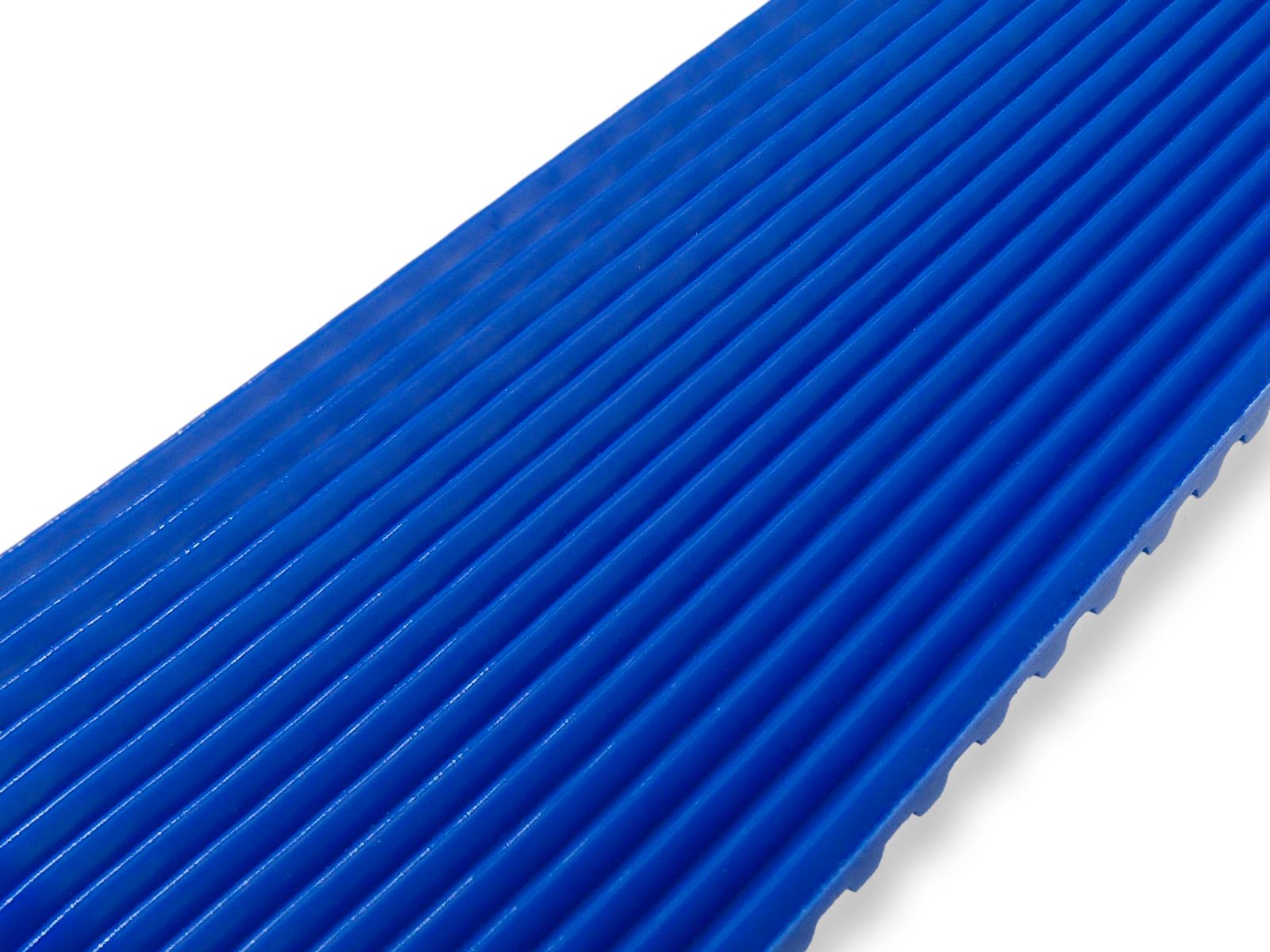

The FDA-approved timing belts, as well as having a smooth back, are available in different geometries which vary depending on the type of product to be transported, offering different advantages.

In the photo gallery on this page you can see some of the available models, and we are available to support you in choosing the solution which best meets your needs.

The materials used to produce these timing belts are highly resistant to many detergents, chemicals, oils and water, and for this reason are used to transport meat, cured meats, fruit, vegetables, bread, biscuits, fish, chocolate, …

It is possible to apply coatings to the rear of the belt with FDA-approved and certified characteristics both via cold gluing and with hot-applied systems.

The first solution is to spread silicone, and this is available in hardnesses of around 30 shore, thus guaranteeing good grip and a high level of adaptability to the transported product; the second involves gluing on various types of coating, including food-grade rubber (60 shore), FDA-approved polyurethane and silicone rubber available in multiple hardnesses from 30 to 65 shore.

The types of belts with cleats, as well as those with generic machining and those for vacuum systems, can be created with the same geometric characteristics as the standard products, but using FDA-approved and certified materials.